Bucket Elevator Chain

Introduction

Maniratan Machinery was established in the year 2017 and since 2020 it has been the Authorized dealer of Renold Chains. Maniratan Machinery is engaged in the manufacturing of Roller Chains, Conveyor Chains, Peg Chains, Stainless Steel Chains, Extended Pin/Rod Chains, Rubber Top Chains, and Biplanar Chains.

Additionally, we also manufacture customized chains based on the sample or picture provided by the customers.

A Bucket Elevator Chain is a specialized conveyor chain used in vertical material handling systems. It consists of interconnected links that support buckets for transporting bulk materials like grains or cement. Designed for strength and durability, these chains ensure reliable operation in demanding industrial environments. Regular maintenance prevents wear and failure.

Key Features Of Bucket Elevator Chain:

Bucket Elevator Chains feature high tensile strength, wear and corrosion resistance, precise pitch control, and customizable bucket attachments. Designed for vertical lifting, they offer durability, fatigue resistance, and easy maintenance in demanding industrial environments.

- High Tensile Strength : Built to withstand the heavy load of vertical lifting, especially with bulk materials.

- Wear Resistance : Uses heat-treated or case-hardened steel to endure abrasion from materials like cement, grains, or coal.

- Corrosion Resistance : Available in stainless steel or coated variants to handle wet, acidic, or chemical environments.

- Precision Pitch Control : Ensures even spacing of buckets, reducing spillage and increasing efficiency.

- Fatigue Resistance : Designed to withstand millions of load/unload cycles without failure.

- Customizable Attachments : Allows mounting of different bucket sizes and types using tailor-made attachments.

- Easy Maintenance and Assembly : Designed with removable pins or bolt-on segments for quicker maintenance.

- Heat Treatment for Durability : Components like pins, rollers, and bushings undergo surface or through hardening.

- Smooth Engagement : Engineered for minimal vibration and noise during operation.

- Standardization and Compatibility : Available in standard sizes and compatible with most elevator configurations.

Types of Bucket Elevator Chain:

- Forged Chain : Made from forged steel for superior strength and resistance to high impact loads. Used in heavy-duty applications.

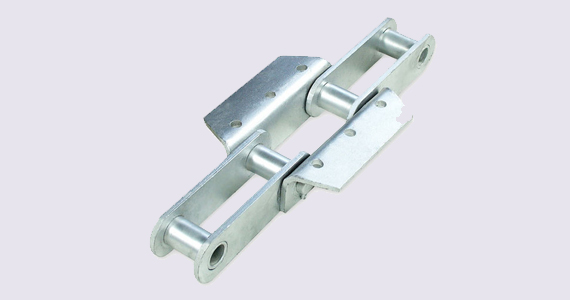

- Roller Chain with Attachments : A standard roller chain with additional links or attachments to mount buckets. Commonly used in light to medium-duty systems.

- Round Link Chain : Composed of round links, ideal for handling abrasive materials. It’s commonly used in highly abrasive environments.

- Bush Chain : Features bushings between the pins and rollers, providing better wear resistance. Used in both light and heavy-duty applications.

- Plate Link Chain : Consists of flat plates linked together, typically for large, heavy-duty bucket elevators. Strong and capable of handling high-load capacities.

- Double Strand Chain : Two parallel chains used for larger capacity bucket elevators. Provides more strength and ensures better distribution of load.

- Triple Strand Chain : Similar to double-strand but with three chains. Provides extremely high strength and is used for the heaviest industrial loads.

- Central Chain : A single chain running through the center of the elevator for vertical lifting. Used in applications where space is tight and high capacity is needed.

- Drop Forged Rivetless Chain : Composed of drop-forged links that do not use rivets. This design makes the chain more durable and suitable for harsh environments.

- Deep Link Chain : Features deeper, wider links, offering additional strength for heavy materials. Often used in cement, grain, and mining industries.

- Hollow Pin Chain : Features hollow pins, which allow for lightweight construction and increased flexibility, used in low-capacity systems or where space is constrained.

Maintenance and Guidelines and tips for Bucket Elevator Chain:

Maintaining a Bucket Elevator Chain involves regular inspections for wear, proper lubrication to reduce friction, ensuring correct tension and alignment, and cleaning to prevent debris build-up. Replacing worn-out chains and monitoring operating conditions help ensure long-term efficiency and prevent failures.

- Regular Inspection : Regularly check the chain for wear, elongation, and alignment. Chains that are too loose can cause buckets to misalign, leading to material spillage or damage.

- Proper Lubrication : Ensure that the chain is adequately lubricated to reduce friction and prevent premature wear. Use high-quality lubricants designed for heavy-duty industrial equipment.

- Correct Tensioning : Ensure the chain is properly tensioned. Over-tightening puts excess strain on the chain, leading to premature failure, while too much slack can cause the system to run inefficiently.

- Material Compatibility : Select the appropriate type of bucket elevator chain based on the material being lifted. For example, abrasive materials (like cement) require chains with higher wear resistance, while corrosive materials (like chemicals) need stainless steel or coated chains.

- Proper Alignment : Ensure that the elevator system is properly aligned. Misalignment of the chain and sprockets can lead to uneven wear and can cause the elevator to malfunction.

- Regular Cleaning : Regularly clean the chains to prevent material build-up, which can cause drag and excess wear. Build-up can also affect the buckets' lifting efficiency.

- Choose the Right Type of Chain : Choose a bucket elevator chain based on the material being conveyed, environmental factors (e.g., temperature, moisture, and chemicals), and required load capacity.

- Replacement Scheduling : Even the most durable chains have a finite lifespan. Plan for regular chain replacements based on usage and wear rates to avoid unexpected failures.

- Training and Operation : Ensure that personnel are trained in proper operating and maintenance procedures. Incorrect operation, such as sudden starts or stops, can damage the elevator chain.

Bucket Elevator Chain Application Industries :

Bucket Elevator Chains are used in a variety of industries where vertical lifting and conveying of bulk materials are required. Some key application industries include:

- Agriculture

- Cement Manufacturing

- Mining

- Food Processing

- Power Plants

- Chemical Industry

- Pharmaceuticals

- Fertilizer Plants

- Recycling and Waste Management

- Petroleum Industry

- Plastic and Rubber Industries

- Pulp and Paper